I haven't really worked on anything new yet. However I did do something I think you might find interesting. My friend has had an XYZ Da Vinci jr. 1.0 3d printer for a couple of years now. It has decided to crap out on him. He asked me if I wanted to try to get it working again. After a "Hell yeah!" (because I love tinkering) he brought it over and I started researching possible causes. Troubleshooting this printer is similar to troubleshooting computer issues, so I did the most obvious things first. Was it plugged in? Was it turned on? Did it have a file to print? So I turned it on. Looked fine. I took the little nozzle declogger and pushed it through a couple of times. Not clogged. So I set it to try one of the standard print jobs already loaded onto the machine.

It printed like 2 inches of the base, then nothing came out of the extruder nozzle. It was still moving like it was extruding, but it wasn't. So I canceled the print job and decided to go further into the extruder. Really give it a cleaning. Maybe there was a clog deeper than my declogging tool could reach.

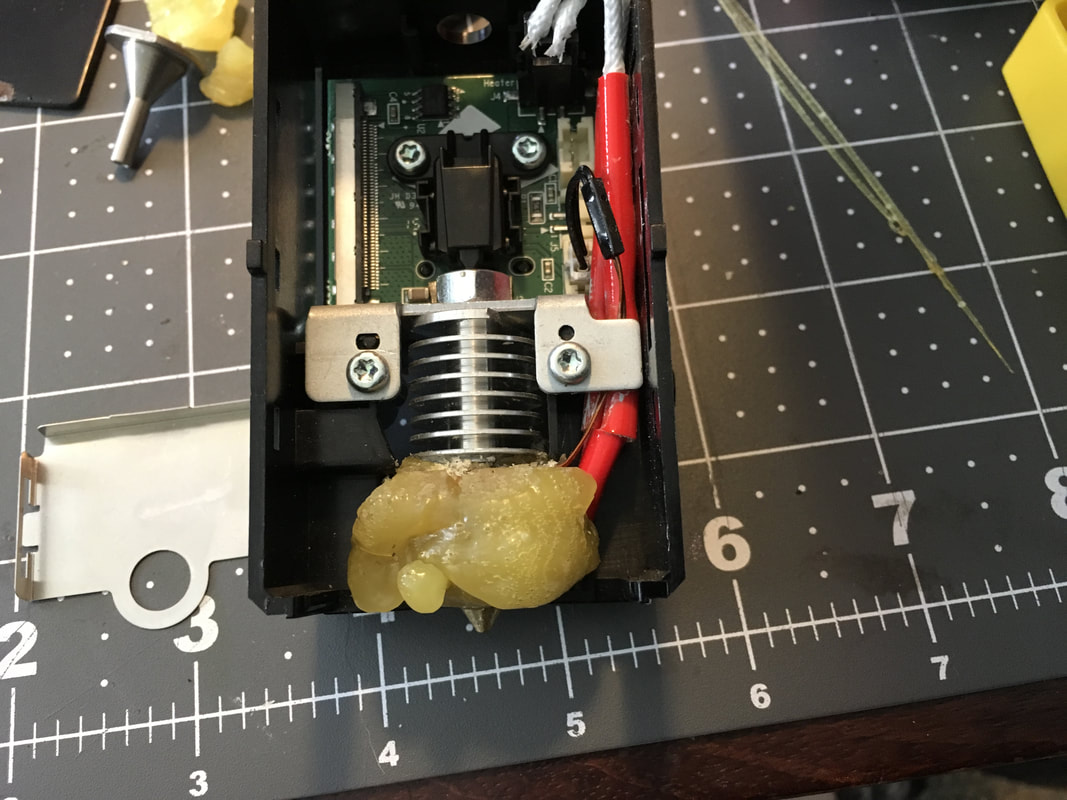

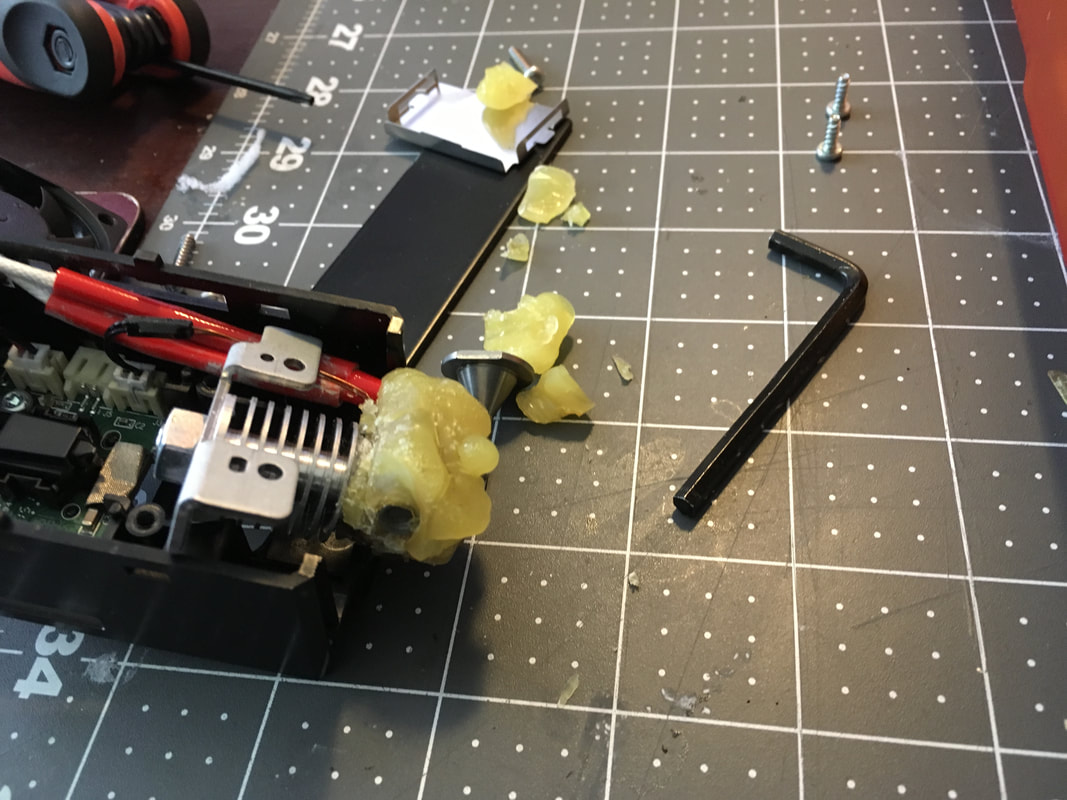

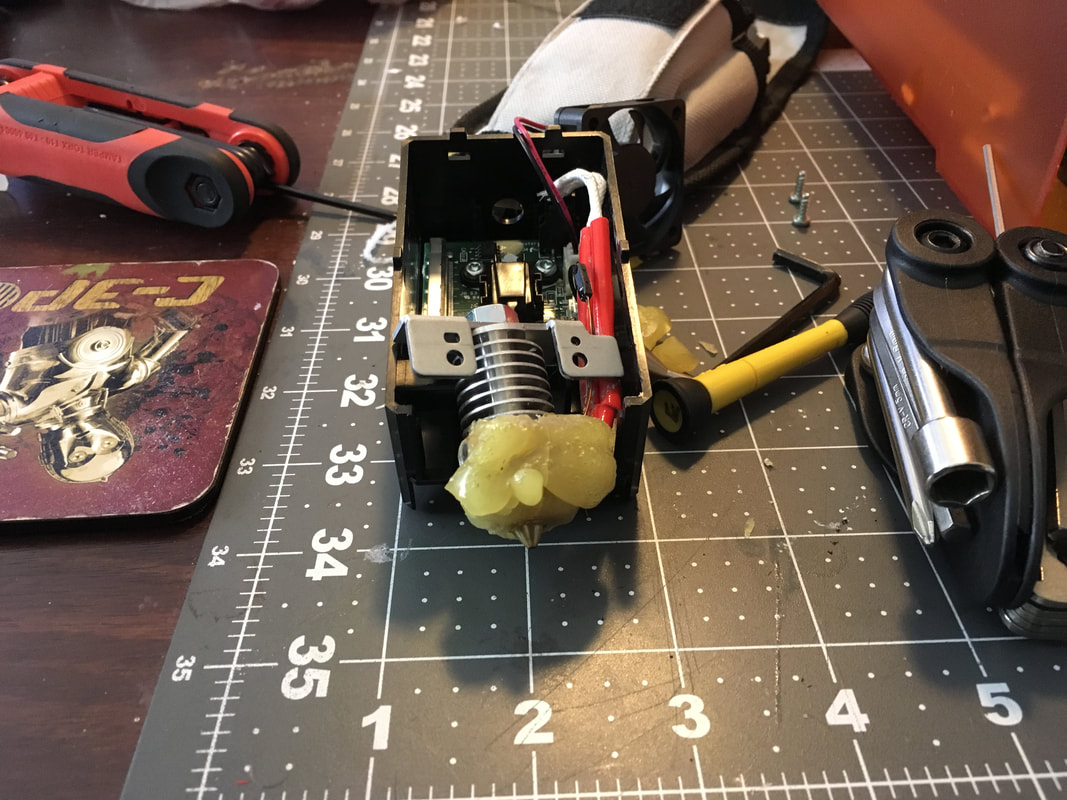

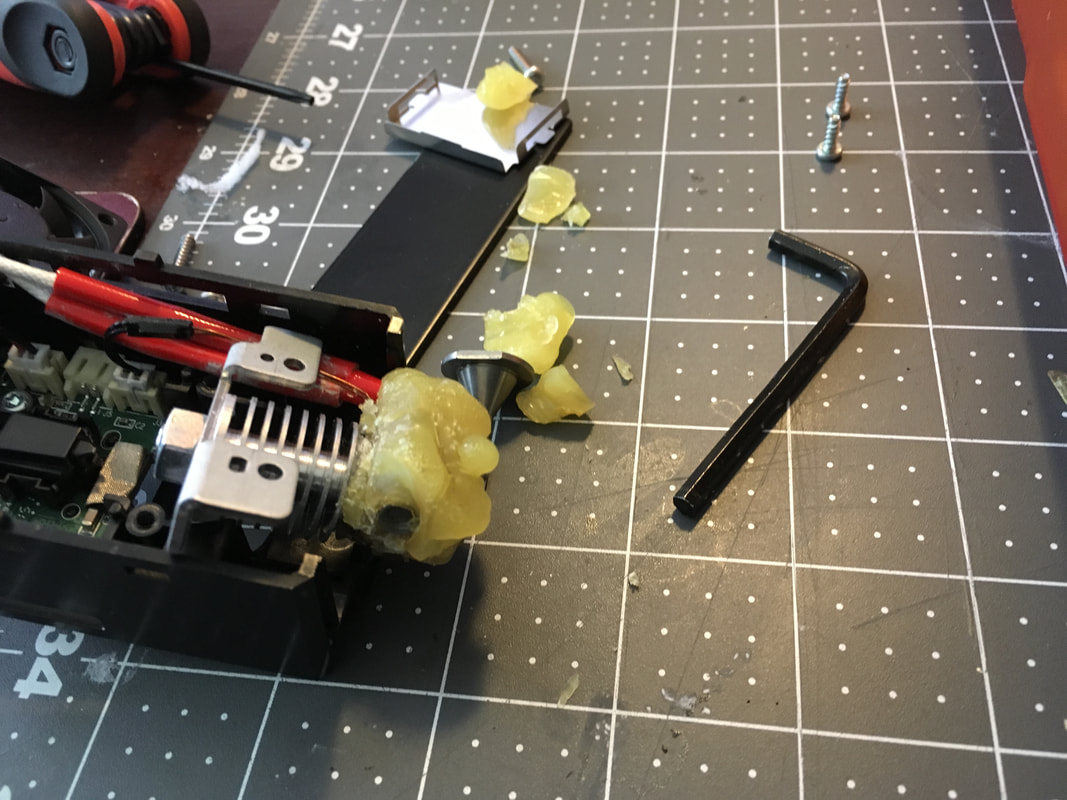

This is what I found inside of the extruder casing:

That is not what is supposed to happen.

While I am unsure the exact cause of this, I have a hypothesis. When I removed the spool of filament, parts of it broke off easily. Just chipped away till way back on the spool. That is also not supposed to happen. This friend got a bad patch from XYZ. Because in this model there is a chip in the spool that allows it to be used. If you get off brand the chip is absent and it won't work. My theory is that it was flaking off inside the extruder and got hot and make this mess. Who knows how many times my friend tried using it that way, adding more and more material until we got here.

However if he had done regular maintenance he might have found this sooner. Might have been avoided, might not. But now, definitely the only options are getting a new exdtruder ($70) or getting a new printer.

You are supposed to do a maintenance check every 200 hours. You should be cleaning the nozzle every other print job. The problem with this model is they advertise it as being low maintenance, which my friend thought meant he didn't need to do anything. Granted, there are newer models available now. This is an older printer. They have been seeling them for at least 3 years. It is possible they fixed any issues like this, or added some kind of sensor system.

But there you go. Nasty mess. I will leave you with more pics of the mess, and come back in a week when I have more progress on my projects to report.

RSS Feed

RSS Feed